Step into a world where tile isn’t just a surface—it’s a story. Original Mission Tile is all about that story, a heritage craft of authentic, handmade cement tiles that are hydraulically pressed, not fired in a kiln. This unique process creates a deep, through-body color that develops a rich patina over time, ensuring the design never fades.

Understanding the Artistry of Cement Tile

Unlike mass-produced ceramic, where a design is just a thin glaze on the surface, handmade cement tile is a piece of functional art. Each tile tells the story of its creation, from the artisan carefully mixing mineral pigments to the immense pressure that locks in the pattern for good. It’s a traditional method that Original Mission Tile has been perfecting since 1900, producing tiles with a distinct character and a silky, matte finish you can feel.

The appeal of this material goes way beyond its beauty. It’s about connecting modern spaces with a legacy of craftsmanship that has deep roots across the globe. You can learn more about this rich history by exploring our guide to cement tiles in European design.

A Heritage Craft for Modern Spaces

The enduring popularity of cement tile isn’t a fleeting trend; it reflects a bigger shift in how we think about design. Homeowners and designers are actively looking for materials that offer both a unique look and sustainable, long-life value. This isn’t just a hunch—it’s a major market force.

The global cement tiles market is projected to expand to between USD 51.5 billion and USD 61.4 billion by 2033. This growth highlights a fundamental consumer preference for eco-friendly, durable building materials.

This incredible expansion shows that authentic, well-made materials are more in demand than ever. Heritage makers have leaned into this by pairing traditional techniques with modern customization, making it possible to create spaces that feel both timeless and deeply personal. You can discover more insights about this growing market and its key drivers.

From residential kitchens that feel like home to high-traffic commercial venues built to last, the applications for Original Mission Tile are boundless. Here’s why people love it:

- Exceptional Durability: The through-body color won’t wear away or fade, making it perfect for floors that see a lot of life.

- Endless Customization: Patterns and colors can be tailored to match any design vision, from a specific paint chip to a vintage fabric swatch.

- Artisanal Character: Each tile has subtle variations that add depth and authenticity—something a machine-made product can never replicate.

This guide will walk you through everything you need to know, from the hands-on manufacturing process to installation best practices.

How Handmade Cement Tiles Are Crafted

So, what gives an Original Mission Tile its soulful, lived-in character right out of the box? It’s all in the process—a hands-on method perfected over a century, a world away from mass-produced ceramics. This isn’t about printing a design on a piece of clay; it’s about building a tile, layer by layer, with raw materials and artistry.

It all starts with a precise mix of Portland cement, fine sand, and marble dust, which forms the tile’s tough core. The magic, though, is in the color layer. We use natural mineral pigments to create hues that are rich, saturated, and deeply ingrained in the tile itself.

Unlike a ceramic tile where the design is just a thin glaze on top, the pattern in a cement tile is a solid, inlaid layer. It’s often a full 1/8-inch thick, meaning it can’t just chip off or fade away. This is the secret to its incredible longevity.

The Art of the Pour

To bring intricate patterns to life, our artisans use a handcrafted metal mold called a molde. Think of it as a heavy-duty, high-stakes stencil, with different compartments for every color in the design.

With an incredibly steady hand, the artisan pours the liquid pigment mixture into each section, one color at a time. It’s a job that requires immense focus and an intuitive feel for how the colors will settle. The thickness of this color layer is what guarantees the pattern will stand up to decades of foot traffic, developing a beautiful patina instead of just wearing out.

Once the vibrant top layer is poured, the metal molde is carefully lifted away. Then, the tile is backed with the sand and cement mixture, giving it the body, strength, and substance it needs.

From Hydraulic Press to Curing Room

Next comes the step that gives these tiles their signature density. Each tile is placed under a hydraulic press that applies an immense amount of force—often over 2,000 pounds per square inch. This intense pressure fuses the layers together into a single, solid piece without using any heat.

This hydraulic pressing process is what truly sets authentic cement tiles apart. There’s no firing in a kiln, making it a much lower-energy, more eco-friendly method. The strength comes purely from pressure, not from heat.

But the tiles aren’t finished yet. They’re moved to a curing room, first submerged in water baths and then left to air-dry on racks for several weeks. This slow, patient curing process is absolutely critical. It allows the cement to hydrate and harden gradually, locking in the color and helping the tile reach its maximum strength.

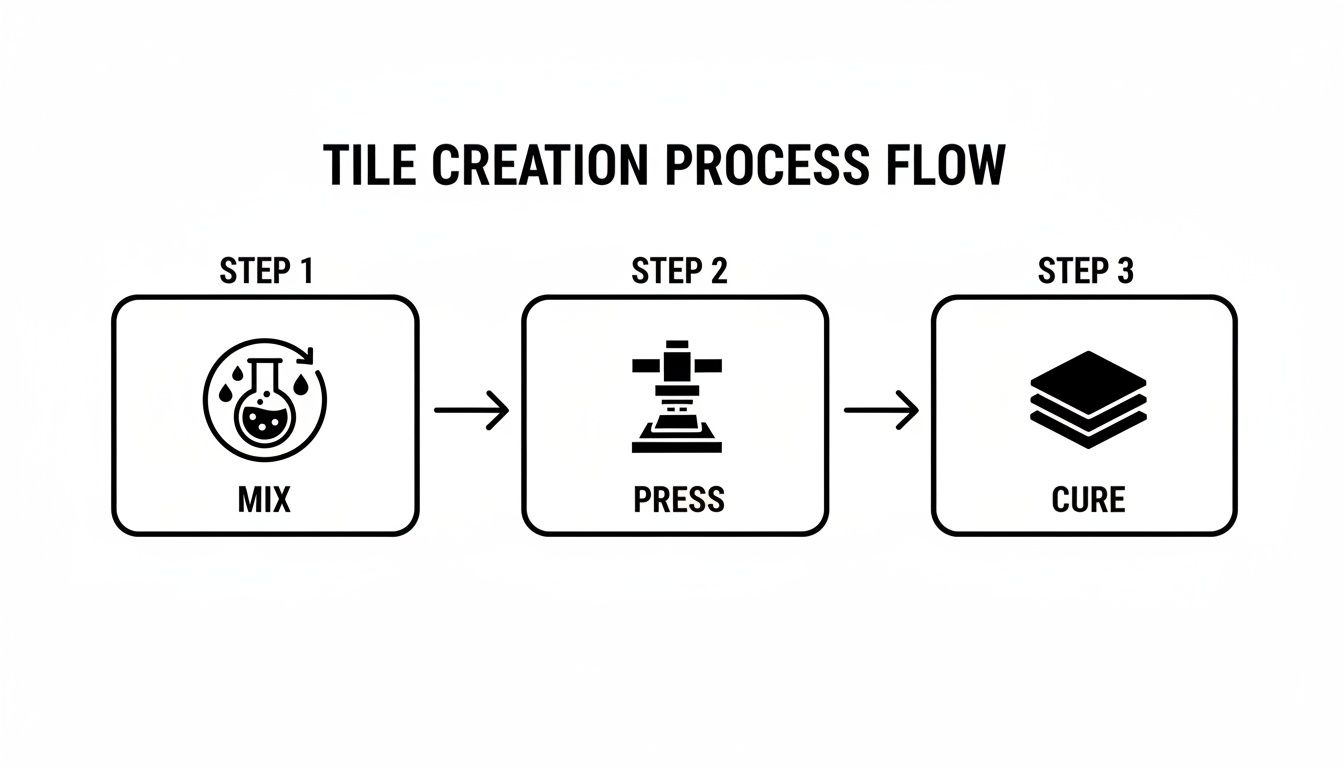

This flowchart breaks down the simple-yet-powerful journey from raw materials to a finished tile, highlighting the key stages of mixing, pressing, and curing.

This intentional, unhurried method ensures that every tile we make isn’t just a building material, but a piece of functional art. The subtle variations in color and texture you’ll see are not flaws—they are the authentic signatures of a truly handmade product.

Why This Method Creates Lasting Beauty

When you understand how these tiles are made, it’s easy to see why they’re specified for high-traffic spots like restaurant floors and hotel lobbies. The tile isn’t just decorated; its beauty is an integral part of its structure.

Here’s a quick recap of the key steps:

- Pigment Mixing: Natural mineral pigments are blended with cement and marble dust to create the vibrant, through-body color layer.

- Pattern Pouring: The liquid color is meticulously poured into a handcrafted metal mold to form the timeless designs.

- Hydraulic Pressing: The layers are fused under extreme pressure, creating a tile that’s incredibly dense and durable.

- Natural Curing: Tiles are submerged in water and then air-dried for weeks to achieve full strength and hardness.

This time-honored technique creates a surface that doesn’t just last—it gets better with age, telling a unique story with every step taken upon it.

Exploring Your Design Possibilities

Your project has a unique story, and your tile should too. Whether you’re on a tight deadline needing something beautiful now or you’re crafting a bespoke masterpiece from the ground up, we’ve got you covered. At Original Mission Tile, our whole approach is built around this balance—offering ready-to-ship classics alongside a powerful studio for complete customization.

This flexibility is key, especially now. The global cement tile market is seeing huge momentum, growing from USD 32.55 billion in 2024 with a projected 8.2% CAGR for the foreseeable future. Why? Homeowners and designers are actively seeking out artisanal, low-maintenance surfaces that feel special. Our blend of in-stock speed and custom creativity directly serves that need for both personality and practicality.

To help you find the perfect fit for your project’s timeline and aesthetic, here’s a quick look at how our design options break down.

Original Mission Tile Design Options at a Glance

| Category | Description | Best For | Lead Time |

|---|---|---|---|

| In-Stock & Ready to Ship | A curated collection of our most popular designs and solid colors, boxed and waiting in our warehouse for immediate dispatch. | Projects with tight timelines; designers and homeowners who need classic, proven looks without the wait. | Ships Immediately |

| Design Studio Customization | An online tool that lets you recolor hundreds of existing patterns using our palette of over 100 colors to create your own unique tile. | Personalizing a specific aesthetic; matching tile colors to paint swatches, fabrics, or branding palettes. | Custom Production |

| Specialized Collections | Unique formats like Star & Cross, Breeze Blocks, and Terrazzo/Brass-inlaid tiles designed to be architectural focal points. | Creating statement walls, partitions, and high-impact features that go beyond standard floors and walls. | Varies by Collection |

In-Stock and Ready to Ship

When your project demands both beauty and speed, our in-stock collection is your best friend. We’ve curated our most timeless and popular designs, boxed them up, and have them ready to go from our warehouse. This collection cuts out custom lead times entirely, without ever sacrificing that authentic, handmade quality.

You’ll find a surprisingly versatile range of formats ready for immediate dispatch:

- Classic 8×8 Squares: The quintessential cement tile format, perfect for floors and walls in both solid colors and iconic patterns.

- Elegant Hexagons: A modern-yet-timeless shape that brings geometric interest to any surface, available in a variety of solid hues.

- Intricate Arabesques: Graceful, curved tiles that interlock to create a flowing, sophisticated pattern for feature walls or elegant floors.

These are the go-to options for designers, builders, and homeowners who need to make confident decisions and keep the project moving.

Your Vision Realized: The Design Studio

For anyone looking to create something truly one-of-a-kind, our online Design Studio is your personal canvas. This interactive tool lets you become the artist, transforming our huge library of patterns into a tile that is 100% yours. The process is straightforward but powerful, opening up countless creative paths.

Here’s how it works:

- Select a Pattern: Start by browsing hundreds of available motifs, from historic reproductions to clean, contemporary geometrics.

- Apply Your Colors: Use our palette of over 100 curated colors to customize every single element of the design. Click, color, and repeat.

- Visualize and Refine: The tool instantly shows you what your creation looks like. You can even see it mocked up in a room setting to be sure it’s perfect.

The Design Studio completely closes the gap between imagination and reality. It’s a direct path to a custom original mission tile that nobody else has.

Specialized Collections for Statement Spaces

Beyond our core offerings, we’ve developed specialized collections meant to create those unforgettable architectural moments. These tiles push past standard formats, bringing in unique textures, shapes, and materials that can define a space.

Whether it’s an entryway, a bathroom floor, or a kitchen backsplash, these collections are crafted to be the focal point of a room. They offer a way to inject personality and high-design character into both residential and commercial projects.

Our specialized collections include some real showstoppers:

- Star & Cross Patterns: This classic pairing creates a beautiful, interlocking design that instantly adds Moroccan or Spanish Colonial charm.

- Decorative Breeze Blocks: Both functional and incredibly stylish, these structural blocks create stunning screen walls and partitions that play with light and shadow.

- Terrazzo and Brass-Inlaid Tiles: For a touch of luxury, these tiles blend the timeless appeal of terrazzo or the warm glow of brass with the soft, matte finish of cement.

From a striking kitchen backsplash to a welcoming patio floor, the possibilities are vast. To explore options that pair well with our tile, you might also consider different concrete patio finishes that can extend your design outdoors. Each collection is another tool to help you define your space. For more ideas, you can also explore our full range of cement tile designs categorized by style.

Inspiring Ways to Use Cement Tile

Looking at a single sample is one thing, but seeing cement tile transform a real, lived-in space? That’s where the magic happens. The true personality of an original mission tile comes to life not on a sample board, but as the foundation of a room’s entire feel. This is where we get to see how these tiles turn everyday surfaces into unforgettable design statements.

Imagine a kitchen backsplash alive with a bold geometric pattern, instantly becoming the room’s vibrant heart. Or picture a primary bathroom floor grounded by the subtle, calming elegance of solid color hexagons. The applications are as broad as your imagination, turning functional areas into curated experiences.

Transforming Key Residential Areas

In a home, cement tile brings a level of character that mass-produced materials just can’t touch. It’s a way to give a space a story and a sense of permanence, from the moment you step through the front door to the most private retreats.

An entryway, for instance, is the home’s first impression. A dynamic, patterned “tile rug” can turn a simple foyer into a grand entrance, setting a sophisticated tone from the get-go. This design trick uses a central pattern with a solid border to define the space, making it feel intentional and welcoming.

In living areas, a fireplace surround tiled in a striking motif becomes an instant architectural focal point. It’s an especially smart move in open-concept spaces, where the tile can anchor the entire room and create a visual center of gravity for the design.

Common residential applications include:

- Kitchen Backsplashes: An ideal spot for a pop of color or an intricate pattern that ties the whole room together.

- Bathroom Floors and Walls: Creates a spa-like feel, with patterns that can range from serene to dramatic.

- Laundry Rooms: Elevates a purely functional space into a delightful one with cheerful patterns.

- Patios and Outdoor Spaces: Extends the home’s design aesthetic outdoors with durable, weather-resistant style.

High-Impact Commercial and Hospitality Design

In places like cafes, boutique hotels, and restaurants, flooring is more than a surface—it’s part of the brand experience. The right tile can define zones, guide foot traffic, and create a signature “brand moment” that guests remember and share online.

For restaurants and hotels, handmade cement tiles offer a powerful blend of durability and premium, handcrafted character. When properly sealed, they are designed to withstand heavy foot traffic while providing an atmosphere that feels intentional and upscale.

This is why designers frequently specify patterned cement tiles for high-visibility areas. A bold pattern in a hotel lobby sets an immediate tone of luxury, while a unique tile in a cafe can become a recognizable element of its identity—perfect for that “Instagrammable” moment.

- Boutique Hotels: Use a cohesive system of patterns to unify the lobby, bar, restrooms, and even outdoor patios, creating a seamless guest journey.

- Restaurants and Cafes: A distinct pattern can zone the bar area from the dining room or create a memorable moment in the restrooms.

- Retail Spaces: A custom-colored tile can reflect brand colors and guide customers through the store with style.

Creative and Unconventional Applications

While floors and walls are the most common canvases, the beauty of original mission tile is how well it adapts to more creative applications. Its substantial feel and matte finish make it perfect for adding texture and artistry in unexpected places.

Consider creating an eclectic patchwork wall by mixing various patterns and solid colors for a unique visual story. This approach is perfect for an accent wall behind a bed or in a creative studio space, adding a bohemian, collected-over-time feel.

Other unique ideas include:

- Stair Risers: Tiling the vertical risers of a staircase with a repeating pattern creates a dramatic and beautiful effect.

- Outdoor Fountains: Adds a touch of Spanish or Moroccan charm to a garden feature.

- Bar Fronts and Countertops: A durable and stylish way to clad the front of a home bar or kitchen island.

Ultimately, these tiles empower you to think beyond the conventional. Whether anchoring a high-traffic restaurant or adding a personal touch to a quiet reading nook, their rich color and handmade character offer a way to make any space truly your own.

Installation and Care for Lasting Beauty

Getting a stunning, long-lasting finish with original mission tile comes down to one thing: a proper installation. Because these tiles are handmade—hydraulically pressed and naturally cured, not fired in a kiln—they have a unique, porous character. This means they need a different touch than standard ceramic tile, one that’s all about protecting them from the very start.

Think of an unsealed cement tile like a beautiful marble countertop. It’s strong and gorgeous, but it’s also absorbent. Without the right protection, it’s vulnerable to stains and moisture. That’s why sealing isn’t just a final step; it’s the most critical part of the entire process.

The Two-Step Sealing Process

To get a resilient, bulletproof surface, you have to seal at two specific moments: once before grouting and once after. Skipping that first seal is probably the most common mistake we see, and it can lead to permanent grout haze and staining.

- Seal Before Grouting: After your tiles are set in the mortar and it’s had time to cure, apply a high-quality penetrating sealer. This first coat sinks into the tile’s pores and creates an invisible shield, stopping the pigments in your grout from bleeding into the tile’s surface.

- Seal After Grouting: Once the grout is applied, cleaned up, and fully cured (this can take up to 72 hours), you’ll apply a final coat of sealer over everything—the tiles and the grout lines. This locks it all in, giving you complete protection from water, dirt, and everyday spills.

A good penetrating sealer doesn’t create a glossy film on top of the tile. Instead, it fills the microscopic pores from within. This is how you preserve that signature silky, matte finish while making the surface incredibly resistant to stains.

Of course, a great installation starts with the right foundation. For detailed guidance on preparing your surfaces, check out our article on proper underlayment for tile floors.

Maintaining the Timeless Finish

The good news? Once your tile is installed and sealed, taking care of it is remarkably simple. The whole game is cleaning effectively without stripping away the protective sealer or damaging the cement itself.

Harsh, acidic, or abrasive cleaners are the number one enemy of cement tile. Your best friend is a gentle routine using pH-neutral cleaners. These products are made specifically to lift dirt without being acidic or alkaline, so they won’t etch the tile or eat away at the sealer.

A simple maintenance plan looks like this:

- Sweep or vacuum regularly to get rid of the loose grit that can act like sandpaper underfoot.

- Mop with a pH-neutral cleaner mixed with warm water according to the instructions.

- Steer clear of harsh chemicals. Never use anything with vinegar, ammonia, bleach, or citrus oils. They can permanently damage the tile’s finish.

Cement Tile Care Dos and Don’ts

To make it even easier, here’s a quick-reference table that breaks down the essentials for keeping your tile looking fantastic for decades.

| Task | Recommended Action (Do) | Action to Avoid (Don’t) |

|---|---|---|

| Daily Cleaning | Sweep or vacuum regularly to remove abrasive grit. Wipe up spills promptly with a soft cloth. | Let spills like wine, coffee, or oil sit on the surface for extended periods. |

| Deep Cleaning | Mop with a diluted solution of a pH-neutral tile cleaner made for natural stone or cement. | Use all-purpose cleaners, vinegar, bleach, or any acidic or abrasive scrubbing products. |

| Long-Term Care | Plan to reseal the tile every 2-3 years, especially in high-traffic or wet areas like bathrooms and kitchens. | Assume the initial seal will last forever. Periodic resealing is essential maintenance. |

Following these straightforward guidelines isn’t just about installing a floor or wall—it’s about protecting a piece of functional art. This mindful approach ensures your investment keeps its integrity and beauty, developing a rich patina that tells a story for a lifetime.

Your Original Mission Tile Questions Answered

When you’re specifying materials, getting clear answers is everything. Whether you’re a homeowner diving into a remodel, a designer sourcing for a client, or a contractor mapping out the install, you need straightforward information. We get it.

Here are the most common questions we hear about Original Mission Tile. Our goal is to give you the practical, real-world guidance you need to plan with total confidence.

What Makes Cement Tile Different From Ceramic Tile?

The real difference comes down to how they’re made and where the color lives. It’s a story of a surface-level pattern versus a design that’s baked right into the soul of the tile.

Ceramic tiles are generally made from clay, fired in a hot kiln, and then a glazed design is printed or painted on top. Think of the pattern as a thin, baked-on layer. An original mission tile, on the other hand, is a completely different animal. It’s crafted from a mix of cement, sand, and mineral pigments that are hydraulically pressed—never fired in a kiln.

The color and pattern in a handmade cement tile are “inlaid” as a substantial top layer, often 1/8-inch thick. This means the design is part of the tile’s body, so it won’t ever fade, peel, or chip away like a surface glaze. This method is what gives cement tile its characteristic silky, matte finish and allows it to develop a beautiful, natural patina over decades of use.

This fundamental difference creates two very different products. One has a printed design on its surface; the other has its design built directly into its core, ensuring a unique, artisanal character that lasts a lifetime.

Can I Use These Tiles in a Shower or Bathroom?

Absolutely. Our cement tiles are a fantastic—and very popular—choice for bathroom floors, shower walls, and full wet rooms. Their ability to carry a bold, seamless pattern can turn a functional bathroom into a truly memorable, spa-like space.

But here’s the key: a successful installation in a wet area is all about following the proper procedure.

Because cement tile is naturally porous, it must be thoroughly sealed during installation to make it water-resistant. This isn’t an optional step; it’s essential for protecting the tile from stains, water absorption, and mineral deposits.

A bulletproof wet-area installation involves:

- Waterproofing the Substrate: Before a single tile goes down, the surface behind it (the shower pan, the walls) needs to be properly waterproofed with a membrane system.

- Sealing Before Grouting: After the tiles are set but before you grout, a high-quality penetrating sealer needs to be applied. This is critical because it prevents the grout’s pigment from staining the surface of the tile.

- Sealing After Grouting: Once the grout has fully cured, a final coat of sealer goes over both the tiles and the grout lines. This creates one comprehensive, protective barrier against moisture.

We also recommend resealing the tiles every couple of years, especially in a high-use shower, to keep that protective layer strong and ensure your tile stays beautiful for years to come.

How Does the Custom Design Process Work?

We built our online Design Studio to make creating a completely custom tile incredibly simple and intuitive. The whole idea was to put the tools of a tile artist directly in your hands, letting you take a spark of an idea and turn it into a finished, one-of-a-kind design.

The process is really straightforward. You start by picking a pattern from our huge library of historical and modern motifs. From there, you can apply any combination of colors from our curated palette of over 100 shades to make a tile that is 100% yours.

You can instantly see your final creation and even mock it up in a realistic room setting. This helps you confirm that the pattern’s scale and the color combo work perfectly with your overall vision. Once you finalize the design, our team gives it a final review and can get a physical sample made for your approval before we start full production.

Just keep in mind that custom orders have longer lead times than our in-stock collections, but the result is an original mission tile made exclusively for your project.

What Is the Lead Time and How Do I Get Trade Pricing?

Lead times can vary quite a bit depending on what you choose, and we have options to fit just about any project timeline.

- In-Stock Collections: For projects on a tighter schedule, our ready-to-ship patterns and solid colors are the perfect solution. These tiles are already boxed up and waiting in our warehouse, and they often ship within just a few business days.

- Custom Orders: Designs you create in our Studio, or any fully bespoke tile, involve a more hands-on production process. These orders typically require several weeks from the time of final approval to when they ship out.

We also offer an exclusive trade program for architects, interior designers, and other building professionals. It’s designed to support your business with benefits like special pricing, dedicated project support from a tile specialist, and free samples for your clients and materials library. You can apply right on our website to join the program and make the specification process seamless for all your projects.

Ready to bring the timeless artistry of handmade cement tile to your next project? Explore the possibilities with Original Mission Tile. https://originalmissiontile.com