A flawless cement tile installation is all in the prep work. Seriously. Skipping the foundational steps is the number one reason I see projects go sideways, leading to cracks, lippage, and a finish that just doesn’t do these beautiful tiles justice.

A perfect install begins way before you mix your first batch of mortar. It’s about a methodical approach that honors the handmade character of the tiles. Unlike machine-made porcelain, every single cement tile has subtle variations. The prep work is what turns those unique characteristics into a stunning, cohesive surface.

Laying the Foundation for a Flawless Tile Installation

This isn’t just about avoiding problems—it’s about setting the stage for a floor or wall that will look incredible for decades. Let’s walk through the non-negotiables.

Inspecting and Blending Your Tiles

The moment your Original Mission Tile delivery arrives, your project has officially begun. Don’t just stash the boxes in the garage. Crack open several of them right away to inspect the tiles. You’re looking for any damage that might have happened in transit and, of course, making sure the colors and patterns are what you ordered.

Remember, minor imperfections and slight color shifts are totally normal. That’s the soul of a handmade product.

Next up is one of the most critical steps in the entire process: blending.

- Mix from Multiple Boxes: Never, ever install tiles straight from one box at a time. Pull from at least three to five different boxes simultaneously. I like to make small stacks around the room.

- Create Visual Harmony: As you pull them, you’ll notice subtle differences in tone. Mix them up! This prevents “blocking” or “patching,” where you get noticeable squares of slightly different shades on your finished floor.

This simple act of blending distributes the beautiful, inherent variations evenly across the installation. The result is a rich, authentic patina, not a checkerboard of mismatched batches.

Preparing the Substrate for Installation

The substrate—the surface you’re tiling over—is the literal foundation of your project. If it’s not perfect, your tile job won’t be either. Whether you’re working with a concrete slab or have put down fresh cement backer board, the rules are the same.

Your substrate absolutely must be:

- Structurally Sound: It needs to be totally rigid. No bounce. No flex. If you walk across the floor and feel any movement, you have to address it before a single tile goes down.

- Clean and Dry: Get rid of every last bit of dust, grease, paint, or old sealer. Anything that gets between the mortar and the substrate will weaken the bond. A shop vac and a damp sponge go a long way here.

- Perfectly Level and Flat: Grab a long straightedge or level and check the floor for high and low spots. Any dips or humps greater than 1/8 inch over 10 feet need to be fixed with a self-leveling compound. Don’t skip this.

Check out this quick-reference table to make sure your surface is ready to go.

Substrate Preparation Checklist

Use this quick-reference checklist to confirm your surface is ready for cement tile.

| Check Point | Requirement | Why It Matters |

|---|---|---|

| Stability | No flex, bounce, or movement. | Prevents tile and grout from cracking under stress. |

| Cleanliness | Free of dust, debris, grease, paint, and sealers. | Ensures a strong, permanent bond with the thin-set mortar. |

| Flatness | No variations greater than 1/8 inch over 10 feet. | Prevents lippage (uneven tile height) and ensures a professional finish. |

| Moisture | Completely dry, with proper moisture barriers in wet areas. | Stops moisture from compromising the mortar or damaging the tile from below. |

Getting these details right is the difference between an amateur job and a pro-level installation that lasts a lifetime.

This attention to detail is more important than ever. Cement tile has grown from a niche product into a major design category, with the global market estimated at USD 32–35 billion for 2024–2025. That growth highlights just how critical proper installation is for protecting the value of your investment.

For wet areas like showers and bathrooms, understanding expert waterproofing techniques is absolutely essential to safeguard your work. And if you’re installing over in-floor heating, the substrate prep is even more critical—check out our detailed guide on installing radiant heat under cement tiles here: https://originalmissiontile.com/radiant-heat-under-cement-tiles-guide/

Mastering Your Layout and Tile Setting Technique

With your surface prepped and tiles blended, it’s time to bring your design to life. This stage is all about precision and patience. Honestly, a well-planned layout is what separates a professional-looking job from one that just feels a little… off.

The goal here is to make sure your cuts are balanced and minimal, especially in high-traffic spots like doorways. The biggest mistake you can make is starting a full tile flush against one wall. That almost guarantees you’ll end up with a sad, tiny sliver of a tile on the other side.

Establishing Your Center Lines

First things first, find the true center of the room. Measure the length and width from a few different points to get an accurate midpoint for each. Snap perpendicular chalk lines right through those points, creating a perfect crosshair in the middle of your floor.

Now, before you even think about mixing mortar, do a dry lay. This is non-negotiable. Just lay out a row of tiles with spacers along each of your chalk lines, running from the center out to the walls. This quick test run is your crystal ball—it shows you exactly how the pattern will end at every edge.

- Adjust for Balance: If you find you’re left with a skinny cut (less than half a tile wide) against a wall, you need to shift your starting point. Nudge your center line just enough so the cuts on opposite walls end up roughly equal and at least half a tile wide.

- Consider Focal Points: Got a fireplace, a big vanity, or another feature that draws the eye? You might want to center your layout on that feature instead of the room’s geometric center. It often creates a more intentional, high-end look.

- Pattern Alignment: A dry lay is also your chance to see how an intricate pattern flows across the space. Check everything carefully. This is the moment to explore different options, and you can learn more about which tile laying pattern works best for your room before you commit.

Taking a little extra time for a dry run saves you from big headaches and ensures the final result is exactly what you had in mind.

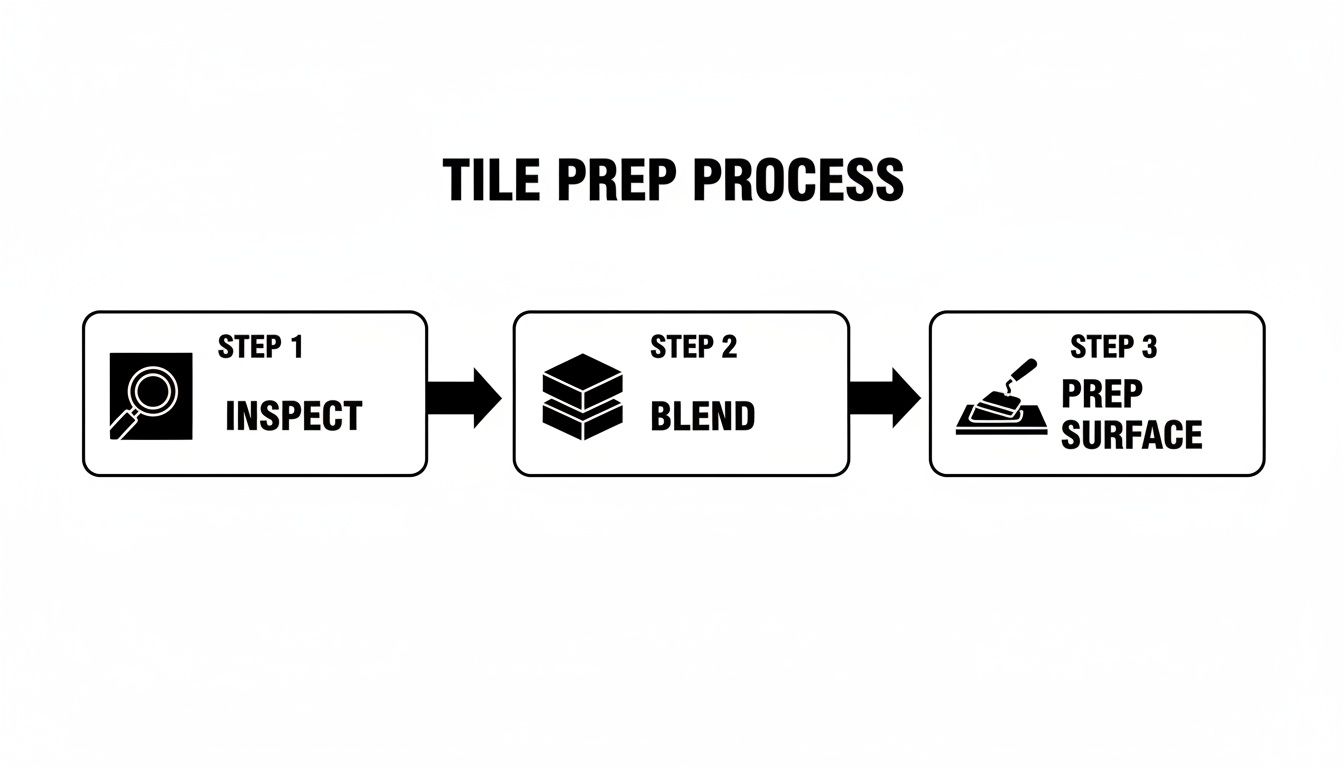

This visual guide breaks down what should happen before you even start thinking about layout.

Inspecting for damage, blending tiles from multiple boxes, and prepping the surface are the foundational steps. Get these right, and the rest of the job will go much smoother.

Mixing and Applying Thin-Set Mortar

Once you’ve locked in your layout and snapped your lines, it’s time to set some tile. The consistency of your mortar is everything. Always, and I mean always, use a high-quality, polymer-modified white thin-set mortar. Gray mortar can and will stain porous cement tiles. Don’t risk it.

Mix the mortar following the manufacturer’s directions until it’s smooth and holds its shape, sort of like creamy peanut butter. You should be able to create ridges with your trowel that don’t slump. Let it “slake” (rest) for about 5-10 minutes after the initial mix, then give it a final stir.

Pro Tip: Only mix as much mortar as you can comfortably use in about 30 minutes. Once it starts to skin over or harden in the bucket, it’s lost its bond strength. Throw it out. Whatever you do, don’t just add more water to “revive” it.

When you’re ready, use a notched trowel to spread an even layer over a small section at a time—maybe two or three square feet. For a standard 8×8 cement tile, a 1/4″ x 3/8″ square-notch trowel is usually the perfect tool for the job.

The Art of Setting and Leveling

With fresh mortar on the substrate, we get to the most critical bonding technique of all: back-buttering. Just before you set each tile, use the flat side of your trowel to skim a thin, even layer of thin-set across the entire back. For cement tiles, this step is absolutely essential.

Why is it so important? Back-buttering guarantees 100% mortar coverage. It eliminates any air pockets or voids that can lead to hollow spots and, eventually, cracked tiles. This complete, solid bond is what gives your floor its long-term durability.

Gently press each tile into the mortar bed with a slight twisting motion to set it firmly. Never use a rubber mallet or beat the tiles into place. Cement tiles are handmade and un-fired, making them more delicate than their ceramic or porcelain cousins. Use your hands to feel and level each tile with its neighbors.

Use tile spacers to keep your grout lines consistent. For cement tiles, a grout joint between 1/16″ and 1/8″ is pretty standard. This small gap helps accommodate the slight size variations that are a natural part of any handmade product and gives the installation a clean, timeless look. Every so often, pull up a tile you just set to check your coverage. The back should be completely covered in mortar.

Cutting and Shaping Cement Tiles for a Custom Fit

No matter how perfectly you map out your layout, you’re going to have to cut some tile. It’s the part of the job that makes a lot of people nervous, but here’s the good news: cutting cement tile is surprisingly straightforward.

Unlike fired ceramic or porcelain, our tiles are noticeably softer. This is a huge advantage if you have the right tools, but it can be a problem if you try to muscle through it with the wrong ones. A high-powered saw meant for porcelain can be too aggressive, leading to chips and breaks. The undisputed champ here is a wet saw with a high-quality diamond blade designed for natural stone or marble. This setup gives you clean, factory-like cuts every single time.

The Best Tools for Clean Cuts

Your wet saw is the star of the show, but having a few supporting players on hand makes all the difference when you’re fitting pieces along walls or around tricky obstacles. A good cutting station will make your life so much easier and your results far more professional.

- Wet Saw with a Diamond Blade: This is non-negotiable for straight cuts. The water keeps the blade cool and cuts down on dust, but more importantly, it lubricates the cut to prevent the pigmented edges from chipping away.

- Angle Grinder: When you need to make L-shaped cuts, notches, or curves around pipes, an angle grinder fitted with a diamond wheel is your best friend. It gives you the freedom of movement a stationary saw just can’t offer.

- Tile Nippers: These are perfect for making those tiny adjustments or nibbling away at an edge to get a perfect fit in a tight corner. There’s a bit of a learning curve, but they’re invaluable for detailed work.

Have these tools ready to go before you even mix your first batch of thinset. Trust me, you don’t want to stop your flow mid-installation to run out for a tool you forgot.

Mastering Straight Cuts with a Wet Saw

Once you’ve marked your measurements, making a straight cut is simple, but it requires a gentle, steady hand. Rushing is the enemy of a clean edge.

Here’s a pro tip: before you cut, run a strip of painter’s tape along your marked line. This tiny step adds support to the tile’s surface and dramatically reduces the odds of chipping as the blade exits the cut. It acts as a stabilizer, holding that beautiful pigmented layer together.

Now, feed the tile into the saw slowly and consistently. Let the blade do the work—don’t force it. A smooth, unhurried pace allows the diamonds to grind the material away cleanly instead of smashing through it. This patient approach is what separates a good cement tile installation from a great one.

Don’t Forget to Dress the Edges: Always take a moment to soften the edges of your cut tiles. A quick pass with a rubbing stone or a high-grit diamond hand pad will knock down any sharpness, giving the cut a factory-finished look and feel. It’s a small detail that makes a huge impact on the final result.

Handling Tricky Cuts and Obstacles

It’s inevitable. You’ll run into a door jamb, an electrical outlet, or a plumbing pipe that lands right where a tile needs to go. This is where your angle grinder and nippers earn their keep.

For a square cutout, like for an outlet, you can make a series of parallel plunge cuts with your wet saw up to your boundary lines, then use nippers to snap out the little sections. An angle grinder also works great here, giving you more freedom to carefully trace your marked lines.

For circular cuts around pipes or toilet flanges, the angle grinder is the best tool for the job. Score the circular outline first, then make a series of small, straight relief cuts from the tile’s edge to the circle. From there, you can gently use your tile nippers to nibble away the waste material until you have your perfect curve. It’s a game of patience—just remove a little at a time until the fit is just right.

The Critical Steps of Grouting and Sealing

This is the stage that makes or breaks your entire project. It defines the final look and, more importantly, the long-term durability of your beautiful new floor or wall. Cement tiles are naturally porous, a lot like a fine natural stone, which means grouting and sealing aren’t just finishing touches—they are absolutely non-negotiable.

If you skip or rush this part of the job, you’re setting yourself up for stains and disappointment. Getting it right is a multi-step journey that actually starts before you even mix your grout, and it’s the key to protecting the vibrant pigments in your tiles for years to come.

Why You Must Seal Before Grouting

Here’s the single most important rule when working with cement tiles: always apply a pre-grout sealer or a grout release. This is an essential first move. Think of an unsealed tile like a dry sponge—if you smear colored grout across its surface, that pigment will sink right into the microscopic pores, causing permanent stains that are a nightmare to remove.

A pre-grout sealer creates an invisible, temporary shield. It fills those tiny pores just enough to stop the grout pigment from grabbing on, which allows for a clean, crisp installation. Just apply a thin, even coat with a foam roller or a lint-free cloth, and be careful not to let it puddle. This simple action is your insurance policy against a stained, muddy-looking job.

By applying a pre-grout sealer, you’re not just protecting the tile; you’re making the cleanup process significantly easier. Grout will wipe cleanly off the sealed surface instead of smearing into the tile itself.

Choosing the Right Grout and Application Technique

Once your pre-sealer has fully cured (always check the manufacturer’s directions for timing), you’re ready to grout. The type of grout you pick here matters immensely.

- Unsanded Grout is Your Best Friend: Cement tiles are typically set with tight grout joints, usually between 1/16″ to 1/8″. For these narrow gaps, unsanded grout is the perfect choice. Its fine texture packs into the joints perfectly without scratching the tile’s surface.

- Color Choice is Key: The grout color you select will dramatically change the final look. A high-contrast grout makes each tile pop, creating a bold, graphic statement. A color-matched grout, on the other hand, results in a more seamless, monolithic appearance. Always, always test your grout on a spare tile first to see how the color looks once it’s dry.

When you start applying the grout, work in small, manageable sections. Use a grout float held at a 45-degree angle to really press the grout down into the joints. Follow that with a second pass, holding the float at a steep, nearly 90-degree angle to scrape all the excess off the tile surface. Work methodically to make sure every joint is packed full and flush.

From an installation perspective, the economics of cement tiles are increasingly attractive when you consider lifecycle costs. While premium handmade cement tiles can cost more per square foot than entry‑level porcelain, market research on flooring shows that durable, low‑maintenance surfaces reduce replacement cycles. This is a huge factor in commercial projects, which often operate on 10–15‑year refurbishment timelines. In that world, correct installation—including proper grouting and sealing—directly protects project margins. Improper techniques can lead to costly callbacks that erase any profit on hundreds of square meters of installed tile.

The Final Seal for Lasting Protection

After the grout has completely cured, which usually takes 24-72 hours, it’s time for the final and most important protective step: applying a high-quality penetrating sealer. This is different from your pre-grout sealer. This is the permanent barrier that will guard against water, oil, and other stains for years.

Look for a sealer specifically designed for porous materials like natural stone or cement. The finish is up to you—some give a completely natural, matte look, while others can slightly enhance the tile’s color. For a comprehensive overview of the process, you can find more detail in our guide on how to seal encaustic cement tiles.

The application process itself is straightforward, but it requires patience.

- Ensure the Surface is Immaculate: Before you start, the tiles and grout must be perfectly clean and completely dry. Any trapped moisture can cause the sealer to fail and leave a cloudy finish.

- Apply Thin, Even Coats: Using a clean, lint-free cloth, a foam brush, or a small foam roller, apply a thin layer of sealer. Work in one direction to ensure even coverage, and don’t let the product puddle.

- Wipe Away Excess: Let the sealer penetrate for about 5-10 minutes (check your product’s specific instructions), then wipe away any excess from the surface with a clean, dry cloth. If you let excess sealer dry on the surface, it can create a sticky, hazy film that’s tough to remove.

- Repeat as Needed: Most installations will need at least two or three thin coats for full protection. The trick is to apply thin layers, allowing each one to dry completely before applying the next.

To test if your tiles are fully sealed, just put a few drops of water on the surface. If the water beads up and sits on top, you’re good to go. If it soaks in and darkens the tile, you need another coat of sealer. After you’ve nailed the grouting, proper sealing is what guarantees your tile will look great for the long haul. For more expert advice on long-term care, you can explore professional tile and stone cleaning and sealing services.

Long-Term Care and Maintenance for Your Tiles

The last tile is set, the grout is wiped clean, and the final coat of sealer has been applied. Your new floor looks incredible, but the work isn’t quite over. Now comes the most important phase: patience. A simple maintenance routine from day one is what will protect your investment for a lifetime.

This final stage is all about letting everything cure. Mortar and grout don’t just “dry”—they undergo a chemical reaction to gain their full compressive strength. Rushing this process is one of the easiest ways to undermine all your hard work.

The Curing Timeline: Patience Is Everything

Think of the curing process as the foundation hardening in place. Even if the surface feels solid to the touch, there’s still a lot going on underneath. Interrupting it can lead to weak bonds and headaches down the road.

Before you start living on your new floor, give it plenty of time to set without any stress. For a typical residential project, this is a reliable timeline to follow:

- Light Foot Traffic: Wait at least 24-48 hours after the final seal before walking on the tiles. If you absolutely have to cross the floor, do it in socks only—no shoes.

- Heavy Foot Traffic: Hold off on allowing regular, heavy foot traffic for at least 72 hours. This gives the grout joints crucial time to achieve significant hardness.

- Moving Furniture: This is a big one. Don’t place or slide heavy furniture like tables, sofas, or appliances for a minimum of 7-10 days. Always lift items into place. Never, ever drag them across the tile, even after it’s fully cured.

For commercial projects with high traffic, I always recommend extending these timelines. It’s a small price to pay for maximum durability.

Your Go-To Cleaning Routine

Once your floor is fully cured, taking care of it is surprisingly simple. The number one rule is to avoid harsh, acidic, or abrasive cleaners at all costs. Products with vinegar, lemon juice, ammonia, or bleach are the enemies of your sealer. They will strip away the protective layer and can even etch the surface of the tile itself.

For daily cleaning, your new best friend is a simple dust mop or a vacuum with a soft brush attachment. This gets rid of the grit and debris that can act like sandpaper over time.

For a deeper clean, stick to a pH-neutral cleaner specifically made for natural stone or cement tiles.

A huge mistake people make is grabbing a generic “all-purpose” floor cleaner, which can be surprisingly acidic. Always check the label for the words “pH-neutral” to be safe. A pH of 7 is neutral; anything much lower is acidic and will slowly eat away at your sealer.

Just mix the cleaner with warm water according to the instructions, mop the floor, and then—this part is important—rinse with a second mop and clean water. That final rinse prevents a soapy film from building up, which can attract more dirt.

Knowing When It’s Time to Reseal

No sealer lasts forever. Foot traffic and regular cleaning will gradually wear down that protective barrier. The good news is that you only need to reapply it every few years, and your tile will let you know when it’s thirsty.

The easiest way to check is with a simple water test. Just spill a little bit of water on a tile in a high-traffic area.

- If the water beads up and sits on the surface, your sealer is still doing its job perfectly. You’re good to go.

- If the water darkens the tile and starts to soak in after a minute or two, it’s time to reseal.

Reapplying a sealer is straightforward. First, give the floor a good, deep clean with your pH-neutral cleaner to get rid of any grime. Let it dry completely—and I mean 100% dry, which might take 24 hours. Then, apply one or two thin, even coats of the same penetrating sealer you used initially, following the same process as before. This simple step restores your tile’s stain resistance and keeps it looking vibrant.

Common Questions About Installing Cement Tiles

Even the most detailed installation plan can leave you with a few questions. It’s a natural part of any hands-on project. When it comes to cement tile, a few specific concerns pop up time and time again.

Getting clear, practical answers beforehand can save you from costly mistakes and keep your project running smoothly. We’ve pulled together the most frequent questions we hear from both first-time DIYers and seasoned contractors, with insights straight from our decades of experience.

Can I Use Cement Tiles in a Shower?

Yes, you absolutely can, but success is all in the prep work. Installing cement tiles in a wet area like a shower demands a zero-tolerance approach to water. The substrate—your backer board—must be completely waterproofed using a quality liquid-applied or sheet membrane system before a single tile goes down.

From there, the tiles themselves need thorough protection with a high-quality penetrating sealer. This isn’t a one-and-done step.

- Pre-Grout Sealing: Apply at least one to two coats. This crucial step prevents grout pigment from bleeding into and staining the porous tile.

- Post-Grout Sealing: Once the grout has fully cured, apply another two to three coats. This seals both the tile and the grout lines, creating a unified barrier against water absorption.

For a shower that sees daily use, plan to reseal the tiles every 1-2 years to maintain that critical protective layer.

What Is the Best Mortar for the Job?

Always, always reach for a high-quality, polymer-modified white thin-set mortar. The color here isn’t just about looks; it’s a technical requirement. Because cement tiles are naturally porous, the gray pigments in standard thin-set can sometimes migrate through the tile, subtly muddying its vibrant colors. White mortar completely eliminates that risk.

A premium modified thin-set gives you the strong, reliable bond these substantial tiles need. If you’re working with larger formats (like 12x12s or bigger) or your substrate has very minor imperfections, a medium-bed mortar is also an excellent choice. It offers better support and helps prevent lippage—those annoying uneven edges between tiles.

Using the right mortar is one of the most fundamental steps. Skimping on quality or using the wrong color is a shortcut that almost always leads to bigger problems down the road.

How Do I Handle a Stain on a Sealed Tile?

Even with a good sealer, spills happen. The key is to act fast. For common organic stains from things like wine, coffee, or oil, a poultice is your best friend.

You can easily make one yourself by mixing a pH-neutral cleaner with an absorbent powder like diatomaceous earth or baking soda until it forms a thick, toothpaste-like paste.

- Spread the paste directly over the stain, making sure it’s completely covered.

- Cover the area with plastic wrap and tape the edges down. This keeps the paste moist so it can do its job.

- Let it sit for 24-48 hours. As the poultice slowly dries, it pulls the stain right out of the tile’s pores.

After you’ve removed the poultice and cleaned the spot, it’s absolutely essential to re-apply a coat of your penetrating sealer to that specific tile to restore its protection.

Ready to bring the timeless beauty of handmade tile to your next project? Original Mission Tile has been crafting authentic, artisanal cement tiles since 1900. Explore our in-stock collections or create your own custom design at https://originalmissiontile.com.